Metallography

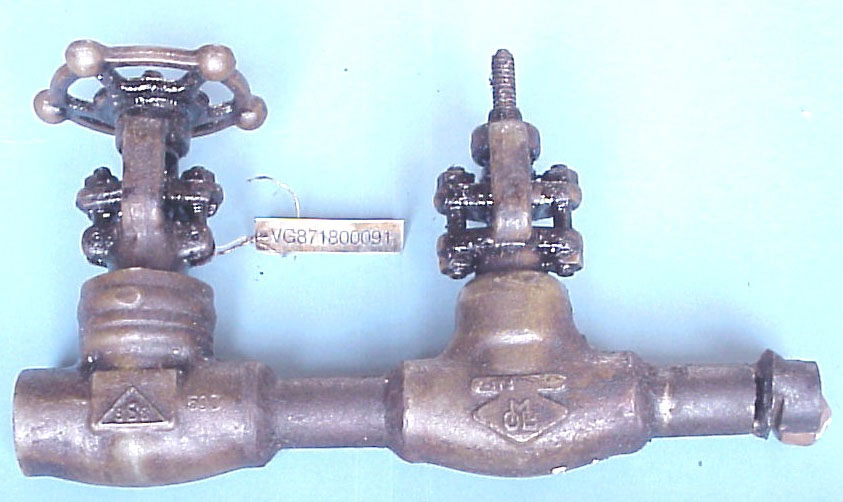

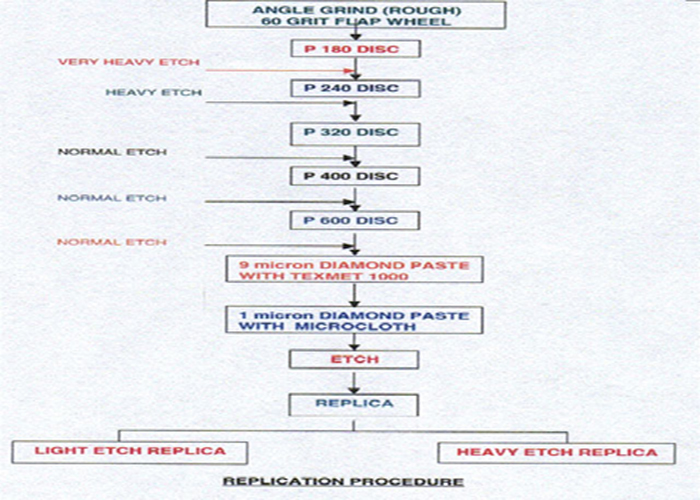

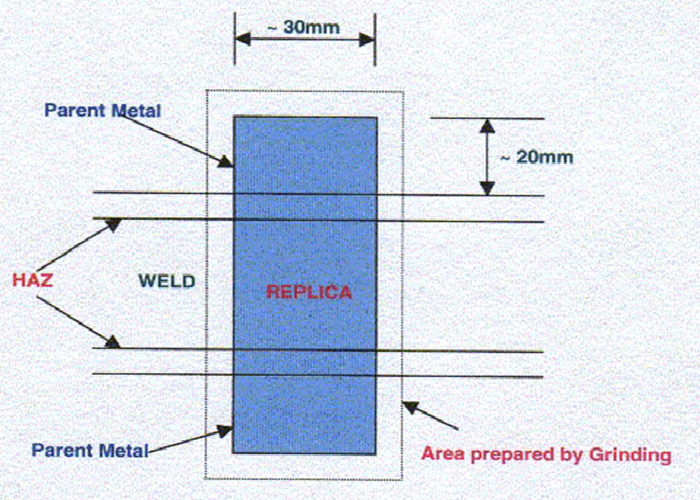

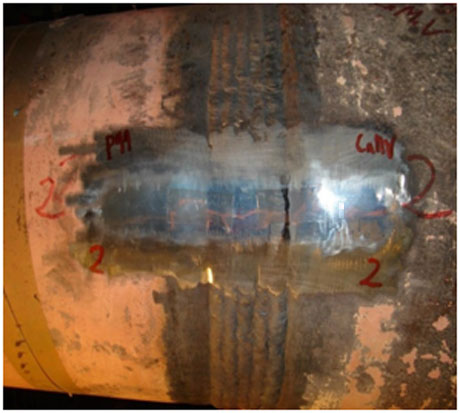

Hands-on Practical Training of technicians in various metallographic methods (in house as well as on-site) such as cutting, grinding, polishing (including electrolytic), mounting, etching (including electrolytic). Training comprises of class room lectures followed by practical demonstration, training notes, examination and certification.

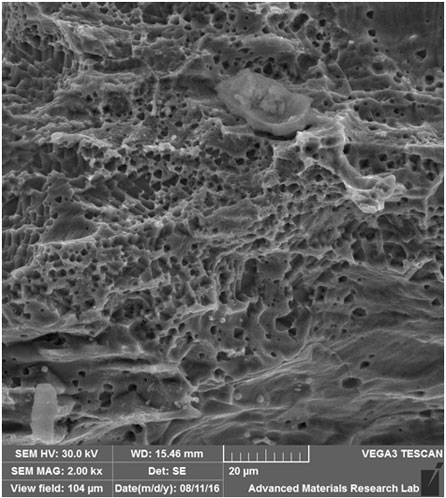

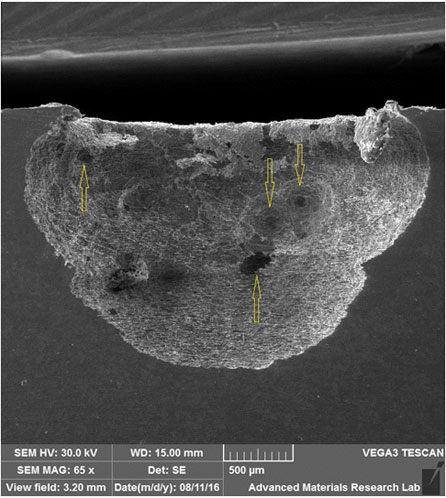

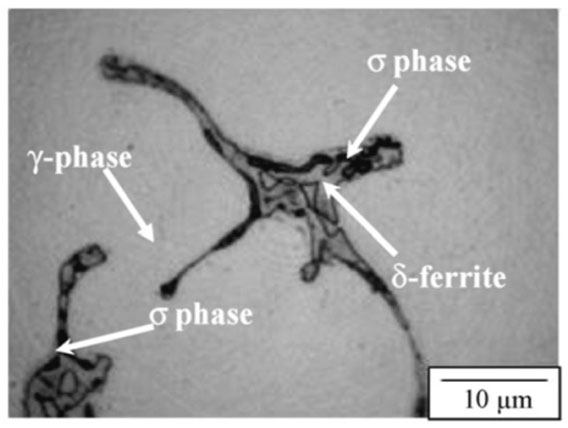

Interpretation of microstructures

Interpretation microstructures of ferrous and non ferrous materials including exotic material such as inconel,duplex,super duplex , HK40 etc..

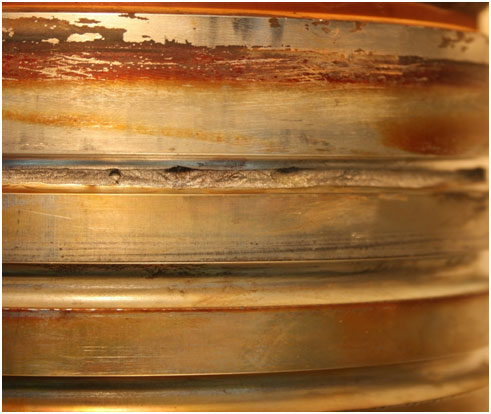

Consultancy for mechanical testing, chemical analysis, condition monitoring and remaining life assessment of industrial components.